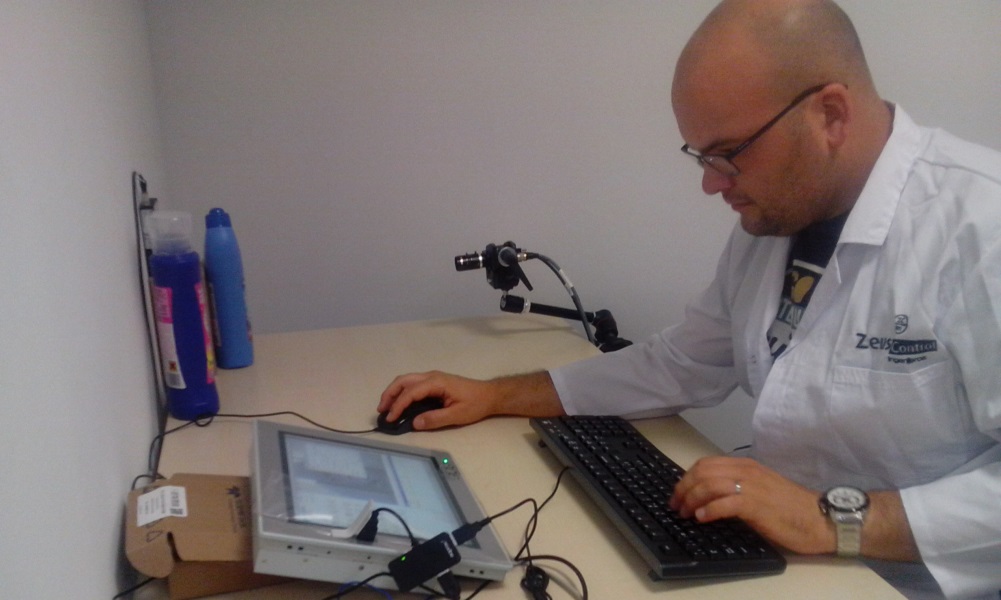

Zeus Control integrates machine vision equipment in production lines or machines by means of turnkey projects. It uses a wide variety of machine vision equipment such as matrix cameras, linear cameras, compact cameras, multi-camera equipment, infrared, and applications with robots.

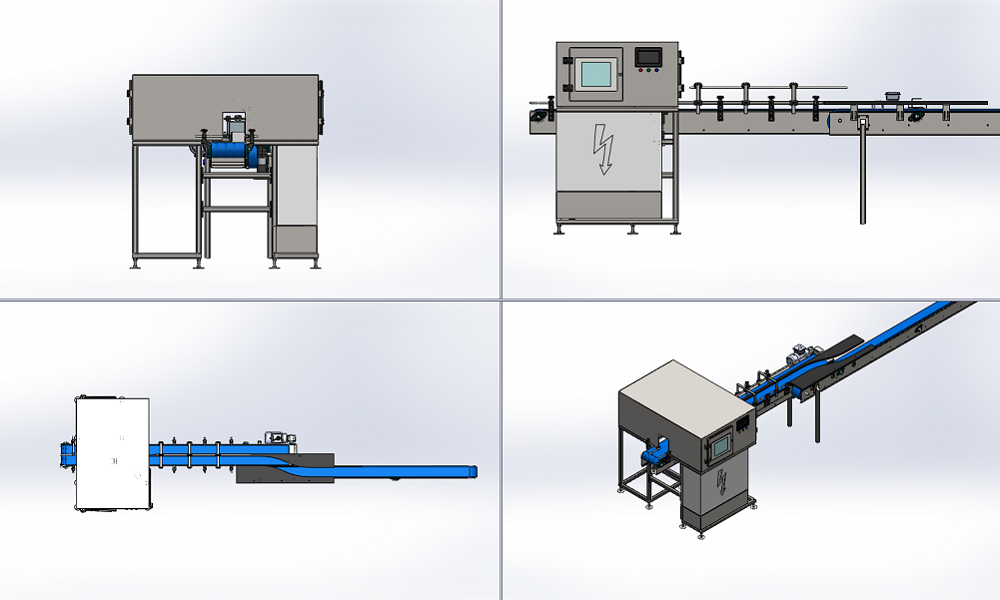

A significant part of the artificial vision projects developed by Zeus Control have taken place in the world of “packaging/bottling”. Successive designs and improvements have led to a “standard equipment”, which is used regularly.

This standard equipment has the following inspection capabilities:

- Stopper: threaded, seal, height, neck, colour and burrs.

- Level: transparent bottles, opaque bottles, foam fluids, transparent fluids and opaque fluids.

- Labels: contour, position, inclination, revision code, integrity, smoothing defects and back label.

- Batch: presence, character integrity, contrast, colour, OCV, OCR and BDD comparison.

- Bar code: decoding, presence, BDD comparison and readability quality parameterization.